Copyright © Shuping Precision Machinery (Nantong) Co., Ltd. All Rights Reserved. Site Map

- +86-18020396606

- hedy@cnccat.cn

- No. 37 Tianfa Road, Economic and Technological Development Zone, Hai'an City, Jiangsu Province

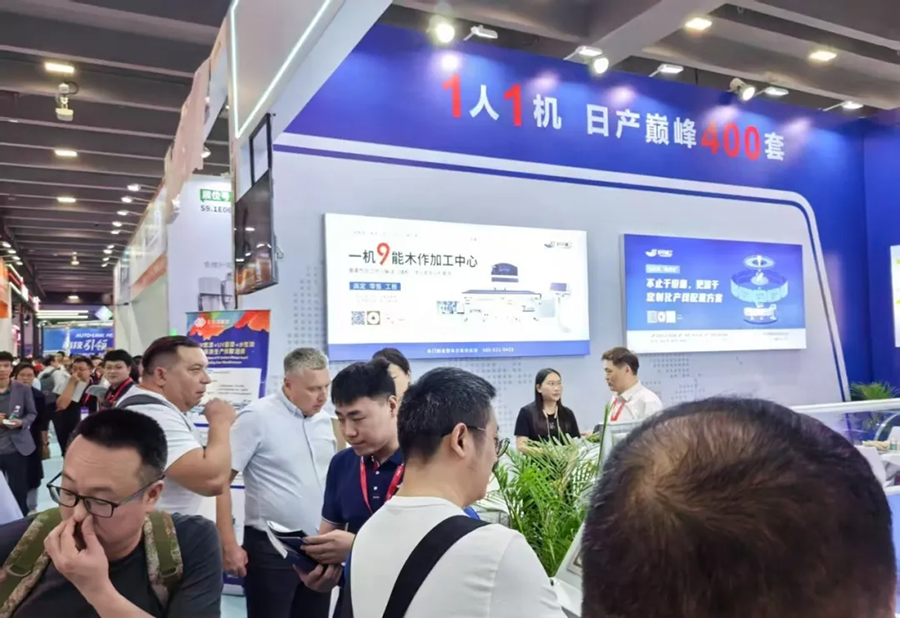

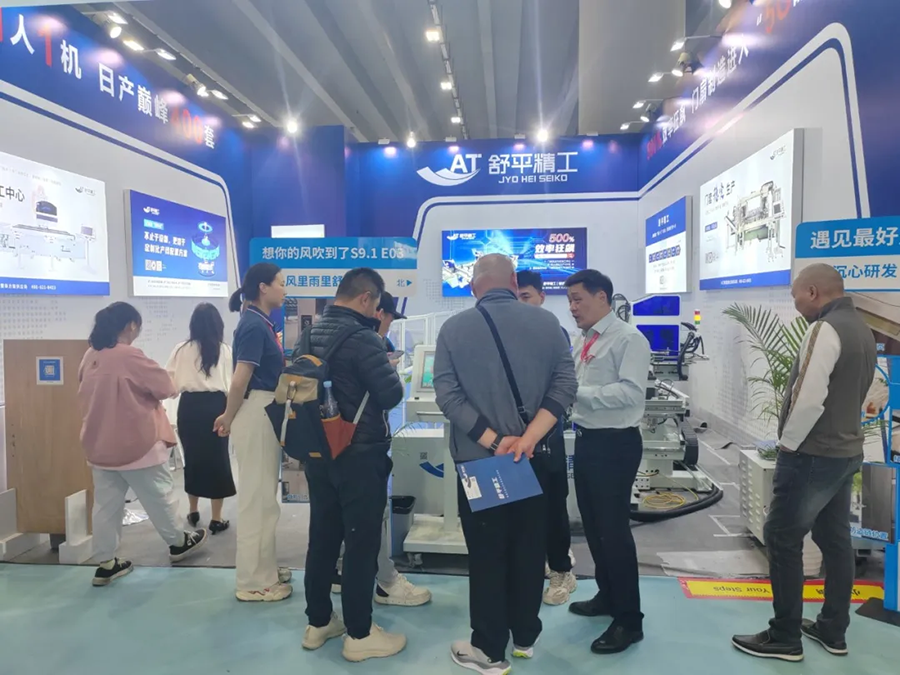

From March 28 to 31, the China International Furniture Fair (Guangzhou) opened grandly. Shuping Precision brought its innovative masterpiece - the door leaf hardware hole processing center to the booth E03 in Hall S9.1, attracting the attention of many industries, bringing new solutions to the wooden door manufacturing field and opening a new chapter in improving the efficiency and quality of wooden door processing.

In the wooden door manufacturing industry, hardware hole processing has long been a bottleneck restricting the increase in production capacity, especially the production of hotel room doors. With the continuous increase in demand in the hotel decoration market, wooden door companies are facing huge production capacity pressure. Shuping Precision's door leaf hardware hole processing center came into being in this context.

This processing center has a high degree of integration and covers almost all the common hardware hole processing functions of wooden doors. From door locks, hinges to latches, nameplates, etc., one device can meet most of the processing needs, which completely changed the cumbersome mode of collaborative operation of multiple devices in the past, greatly reducing the time spent on equipment switching and process connection, and reducing the probability of errors.

In terms of efficiency improvement, the equipment is full of innovative highlights. Its cutting tool has been deeply optimized, using advanced materials and unique design, with excellent cutting performance, and can quickly and accurately cut into wood, effectively shortening the processing time while ensuring hole accuracy and surface quality. The intelligent algorithm replans the processing path, avoiding empty strokes and repeated operations in traditional processing, and further improving processing efficiency. The equipment has been upgraded in the movement, positioning and adsorption of door leaves, and related operations can be completed within 10 seconds. Fast and accurate positioning provides a solid guarantee for continuous and efficient processing. The no-load moving speed of the machining center head has been increased from 30 meters per minute to 60 meters per minute for the same type of equipment, greatly shortening the processing cycle. It is worth mentioning that the equipment has the function of simultaneous processing on three sides. A single person operating a device can produce up to 400 sets per day. Compared with the traditional mode of two people producing 100 sets per day, the production efficiency has achieved a qualitative leap, with an increase of more than 5 times.

Hotel doors are usually 80MM thick, and the performance requirements of processing equipment are strict. With its strong processing capabilities, Shuping Precision Door Leaf Hardware Hole Processing Center can easily meet the processing needs of hotel doors and provide reliable technical support for hotel door manufacturers.

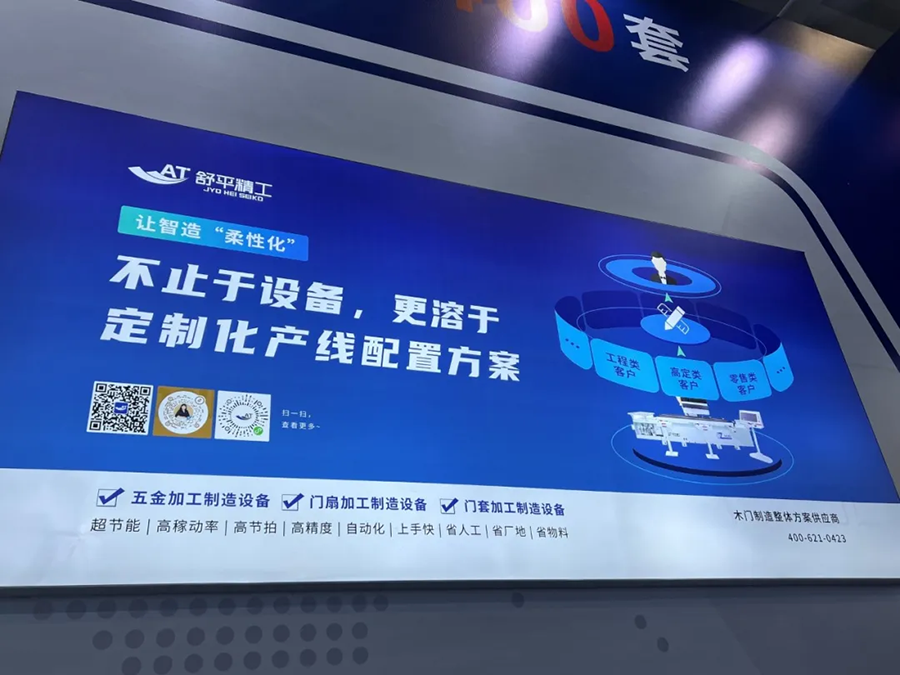

In addition to its efficient processing capabilities, the equipment also performs well in energy saving, consumption reduction, cost reduction and efficiency improvement. It occupies a small area, saving the company's site costs. low electricity and gas consumption, reducing operating costs. convenient docking with the MES system, helping companies to achieve intelligent production management and quality monitoring, and empowering the company's development in all aspects.

At the exhibition, Shuping Seiko also demonstrated its strength as a supplier of overall solutions for wooden door manufacturing. From hardware processing and manufacturing equipment to door leaf and door cover processing and manufacturing equipment, the product line is rich and diverse, with many advantages such as ultra-energy saving, high utilization rate, high beat, high precision, high degree of automation, fast start-up, labor saving, site saving, material saving, etc., providing customized production line configuration solutions for companies with different needs.

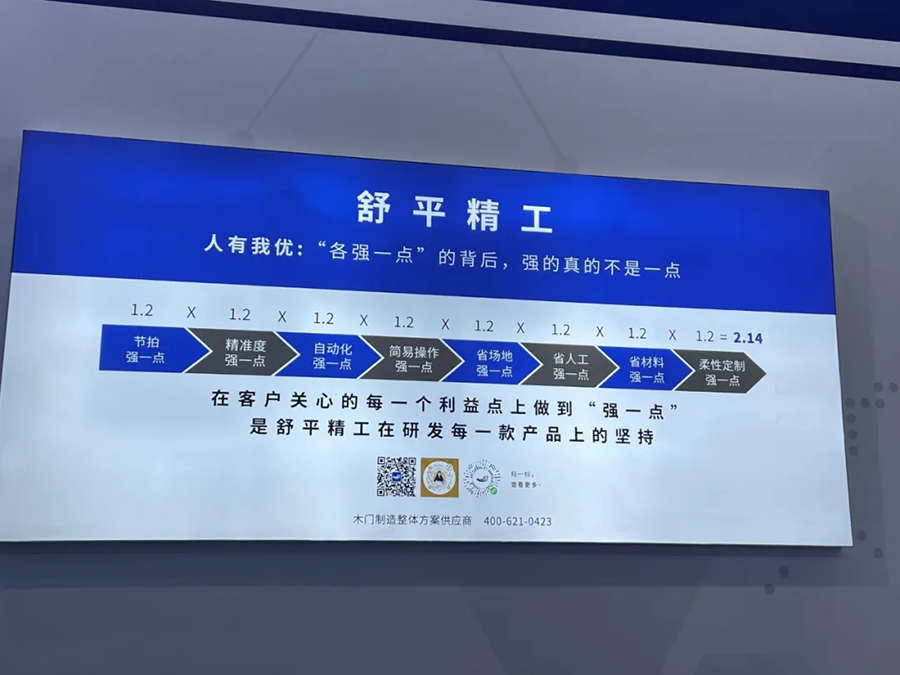

Shuping Seiko has always adhered to the concept of "I am better than others, and each is stronger", and has continued to deepen its interests in beat, precision, automation, simple operation, site saving, labor saving, material saving, flexible customization and other customer-concerned interests. The participation in the China International Furniture Fair (Guangzhou) not only showcased the company's innovative achievements, but also demonstrated its determination and strength to lead the development of the wooden door processing industry. In the future, Shuping Precision is expected to continue to rely on technological innovation to bring more surprises to the wooden door manufacturing industry and promote the industry to continue to develop in the direction of efficiency, intelligence and greenness.