Copyright © Shuping Precision Machinery (Nantong) Co., Ltd. All Rights Reserved. Site Map

- +86-18020396606

- hedy@cnccat.cn

- No. 37 Tianfa Road, Economic and Technological Development Zone, Hai'an City, Jiangsu Province

In the home furnishing industry, KENTIER can be regarded as a well-known brand. From its early founding in 2003 to the present, it has developed into a large home furnishing enterprise with more than 2,000 acres of production bases in Danyang, Jiangsu, Lianshui, and Chuzhou, Anhui. Especially in 2015, the acquisition of the CBA Jiangsu Men's Basketball Team was made famous by KENTIER.

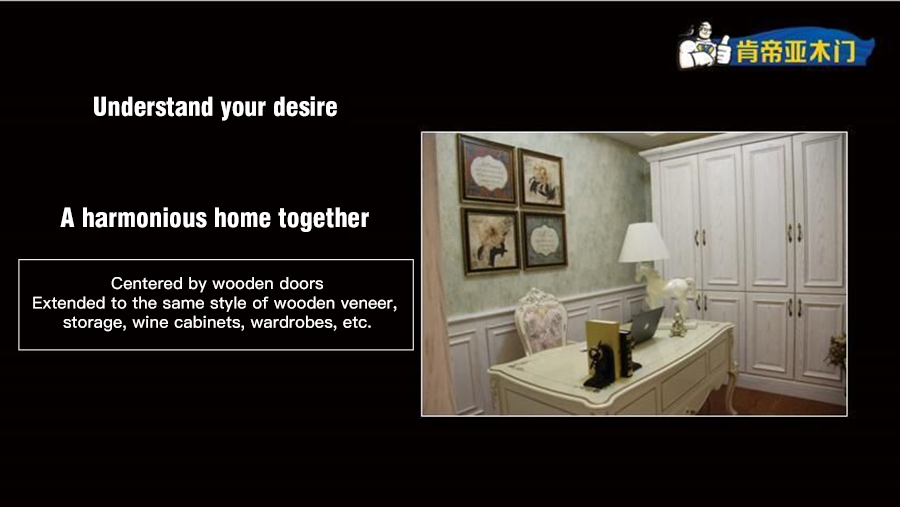

As part of the KENTIER Group, KENTIER wooden doors have basically completed the process of expanding from wooden doors to home furnishings, and are moving towards intelligence. At the same time, KENTIER wooden doors have been deeply engaged in the engineering field and have gradually transformed themselves from a manufacturing enterprise to a solution supplier in the real estate industry.

Entering 2019, due to the influence of the market and the environment, the wooden door industry has shown increasing difficulties and slowing down its development. Against this background, the calls for "transformation and upgrading" are becoming increasingly strong. In addition to soft changes in thinking mode and management mode, equipment updates and transformation are inevitable real investments. How to exchange less investment for the greatest return in transformation and upgrading is a concentrated reflection of the level of enterprise management and capital use efficiency.

Looking back at KENTIER wooden door, it can be said that every period of development is in transformation and upgrading. It is this transformation and upgrading concept that is maintained at all times that enables it to develop rapidly. So, how did KENTIER choose equipment?

Regarding this issue, KENTIER responded that they began to use Shuping Seiko's woodworking equipment in 2013 and have been using it well. "If we want to score Shuping Seiko, we will score 95 for it!"

Shuping Seiko was founded in 1995. It has done 15 years of OEM OEM for famous Japanese companies and has accumulated rich experience in R&D, design and manufacturing of wood processing equipment. In 2010, Shuping Seiko began to launch products to the domestic market, and quickly opened up the situation in China with the advanced nature of the equipment and the characteristics that conform to the operating habits of the Chinese people.

After entering the domestic market, Shuping Seiko has always made it more in line with the habits of Chinese people, has higher processing accuracy, and is more helpful in reducing people and improving efficiency. At present, the equipment accuracy error has been controlled within 20 wires. The functional combination of Shuping Seiko equipment is also very outstanding. For example, the DF45 door cover machining center includes various functions such as fixed length, milling, sawing, and locking tongue hinge processing. Shuping Seiko equipment has also reached a very high level of intelligence in door leaf and door sleeve processing, and the docking between the production line and the enterprise production management system has also been fully realized - in the production task list, Shuping Seiko's independent research and development software can automatically generate processing barcodes and automatically process them according to the barcodes. In terms of easy operation of equipment, the company sends people to Shuping Seiko to learn, and it can be learned in three to four days. According to statistics, compared with ordinary CNC production lines, Shuping Seiko production line personnel savings can reach up to 90%, and the output will increase by more than 1/3. With the same output, Shuping Precision Equipment Energy Consumption is only 1/3 of that of ordinary CNC production lines, and the area is reduced by 50%.

KENTIER wooden doors said that when choosing Shuping Seiko equipment, the first thing to do was to pay attention to its good performance and high efficiency. During the procurement, installation, commissioning and after-sales service, Shuping Seiko also showed a high level of service professionalism. Before purchasing, Shuping Seiko conducted in-depth communication with KENTIER and customized the plan according to needs. Contact KENTIER in advance before shipment to let the factory prepare installation conditions. During the installation, the master patiently conducted training and explained all the situations. Revisits from time to time every year.

KENTIER wooden doors give high evaluations for the ease of operation and accuracy of the equipment: the Shuping Seiko system has a fixed operating template, and as long as the size is entered, it can produce accurate and meet industry standards.

KENTIER Wooden Door said: I have done well in all aspects. If I can score, I think I can score 95 points!

The selection of equipment is indeed a major event for wooden door companies - one is to invest a lot, and the other is whether it can meet the processing requirements and whether it is suitable for you. If the equipment is not used well after buying it, the accuracy is not met, the equipment manufacturer only sells it and does not serve it well... are all problems and traps that wooden door companies may face. Learning and learning from successful big companies and brands can minimize problems and avoid encountering traps. Here, I would like to express my sincere thanks to the KENTIER wooden gate who told me frankly! At the same time, we also pay tribute to Shuping Seiko, which provides equipment for the Chinese wooden door industry with international processing and domestic consumption level!